Efficient Tube Cutting for Fitness Equipment: Compact, Fast, and Built for Manufacturers

In the competitive world of fitness equipment manufacturing, success depends on delivering strong, safe, and precisely engineered products—quickly and cost-effectively. As more manufacturers shift toward automation and lean production, laser tube cutting has emerged as a vital tool in modern gym equipment fabrication. This article explores how compact laser tube cutting solutions are transforming the […]

Laser Cutting Application in Shipbuilding Boosting Precision, Cost-Efficiency, and Sustainability

The global shipbuilding industry faces three key challenges: shorter delivery cycles, rising material costs, and increasingly stringent environmental regulations. To address these challenges, leading shipyards have begun adopting laser cutting technology on a large scale. From luxury yacht manufacturers in Europe to commercial ship production hubs in Southeast Asia, laser cutting machines are redefining the […]

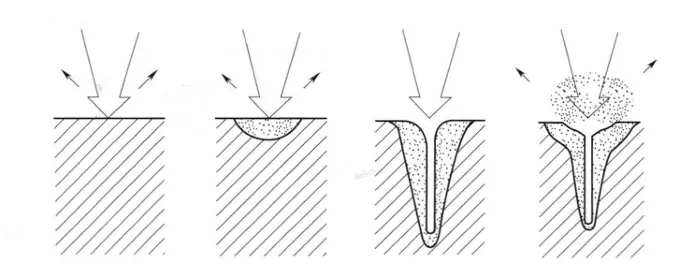

Application of laser technology in steel cutting and processing

Laser Technology Principle Laser Generation and Characteristics Laser is a highly coherent and monochromatic light beam generated by stimulated radiation. The generation mechanism of laser involves atoms or molecules jumping from a low energy level to a high energy level under the action of external energy (such as electric current, light or chemical reaction), and […]

The significance of the plate cutting machine to form complex bevels in one cut

Plate cutting machines have become indispensable tools in modern manufacturing, particularly in industries that require precise and efficient cutting of metal components. One of the most significant advancements in this field is the ability of these machines to create complex bevels in a single cut. This capability not only enhances the quality of the finished […]

Maximizing Precision: The Power-Thickness Equation in Laser Cutting

Laser cutting technology has revolutionized the manufacturing industry, providing precise and efficient methods for cutting various types of metals. One of the most critical factors influencing the effectiveness of laser cutting is the relationship between the power of the laser and the thickness of the metal being cut. Understanding this relationship is essential for optimizing […]

Winter Maintenance and Care of Laser Cutting Machines

Winter presents unique challenges for laser cutting machines, especially in regions that experience extreme cold. Proper maintenance and care during this season are essential to ensure optimal performance and longevity of the equipment. This article outlines key strategies for winter maintenance and care of laser cutting machines, focusing on preventing damage from freezing temperatures and […]

Research on laser welding forming control technology——Principle and characteristics

Mechanism and control technology principles and characteristics of laser welding The development trend and characteristics of modern vehicles are high-speed operation and lightweight structure. Therefore, higher requirements are put forward for the manufacturing of key structures, such as lightweight, integration, high reliability, long life and low-cost green manufacturing. To this end, high-energy beam welding with […]

Taglio laser vs. rivestimento laser

Laser cutting is a modern manufacturing process that utilizes focused light energy to cut through various materials with high precision. The term “laser” stands for “light amplification by stimulated emission of radiation,” which describes how lasers work by concentrating light to produce extreme temperatures that melt or vaporize materials. This technology has transformed traditional manufacturing […]

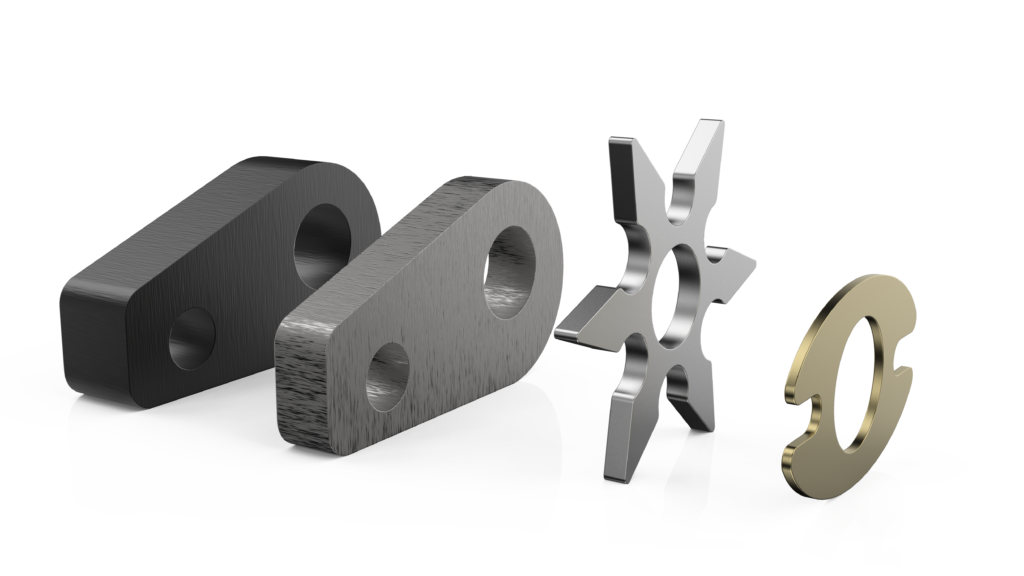

Il ruolo importante del taglio laser del tubo prima della piegatura del tubo

In metal fabrication, tube laser cutting is crucial before the bending stage. This technique not only cuts but also ensures precision and quality in later processes. Tube laser cutting enables detailed designs and clean edges, which help maintain the tubes’ strength and appearance during bending.The importance of tube laser cutting is significant. With laser technology, […]

È necessario acquistare un controllo di qualità della macchina per il taglio laser?

Key Considerations in Laser Cutting Machine Quality Inspection Factor Description Importance Inspection Frequency Determines how often inspections should be performed to maintain optimal machine function. Regular inspections prevent wear and tear, keeping productivity high and minimizing unexpected costs. Precision and Calibration Ensures the machine operates with optimal precision, essential for industries requiring tight tolerances. Calibration […]