What is a laser tube used for?

Lasers are a powerful tool with a wide range of applications, from medical treatments to manufacturing processes. In order to produce the laser beam, a laser tube is often used. A laser tube is an essential component for many laser systems because it helps to generate and regulate the power of the beam. This article […]

How to open up new design possibilities with tube laser cutting machines

What is Tube Laser Cutting? Tube laser cutting is a revolutionary process that allows for the manufacture of complex shapes and designs in metal tubing. This cutting technique offers many advantages over traditional methods, such as improved speed and accuracy. It also opens up new design possibilities for manufacturers, allowing them to create intricate shapes […]

Unlimited guide of tube laser cutting

Tube laser cutting has become a popular and efficient way of cutting, drilling and welding various materials in the manufacturing industry. It offers a number of advantages compared to traditional methods, including flexibility, precision, speed and cost-effectiveness. This article provides an unlimited guide to understanding the basics of tube laser cutting technology and its applications. […]

How to choose a tube laser cutting system to optimize production

Introduction Choosing the right tube laser cutting system is essential for optimal production. With the right system, you can maximize efficiency, accuracy, and cost savings. This guide will provide an overview of the factors to consider in selecting a tube laser cutting system, including the type of tube you are using, the size and shape […]

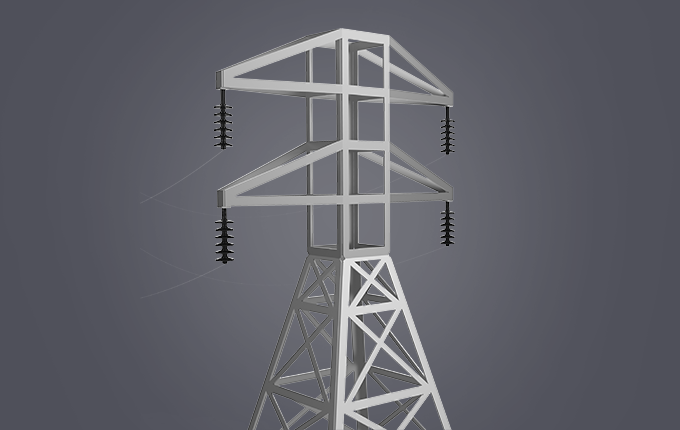

Tube laser cutting machine: mainly used for cutting various metal hollow round tube materials

Introduction Tube laser cutting machine is a modern cutting technology used for cutting various metal hollow round tube materials such as aluminum, copper, brass, and steel. It is a precise, high-speed, and cost-effective cutting method that is used in a variety of industries. The laser beam is focused on the tube to be cut and […]

The effect of laser cutting parameters on the formability of complex phase steel

Complex Phase Steel Formability of Steel Complex phase steel is a type of high-strength low-alloy steel that has been developed to meet the needs of industry. It is known for its excellent formability and strength, making it ideal for applications such as automotive body parts and building components. Recent research has shown that laser cutting […]

How to improve your tube beam laser cutting skills: the basics to know

Introduction Tube beam laser cutting is one of the most versatile and efficient methods of cutting materials in today’s industrial world. If you’re looking to improve your skills in this area, there are a few basics to know. In this guide, we’ll cover the basics of tube beam laser cutting, including the different types of […]

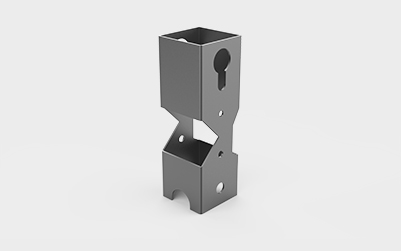

How to improve tube laser cutting parts

Introduction Tube laser cutting parts are used in many industries and are essential for many projects. With the advancements in laser cutting technology, it is now easier than ever to produce high-quality parts. This article will provide tips on how to improve tube laser cutting parts. By following these tips, you can get better results […]

Factors affecting laser cutting tailing

Introduction Laser cutting is a widely used process for cutting or engraving materials. It is a highly precise process that produces clean and accurate cuts, but it is not without its flaws. Laser cutting tailing is a common issue in laser cutting that can cause inaccuracy and inconsistency in the cut pieces. It is important […]

Why is laser cutting more efficient than plasma cutting?

Introduction Laser cutting and plasma cutting are two of the most common industrial cutting methods used in the manufacturing industry. Both processes are used to cut through a variety of materials, including metal, plastic, and even wood. While both methods have their advantages, many experts agree that laser cutting is more efficient than plasma cutting. […]