Control System of Laser Cutting Machine for Profiles

Special-shaped materials, such as square tubes, rectangular tubes, oval tubes, flat tubes, U-shaped tubes, channel steels, I-beams, etc., are widely used in the furniture industry, display shelves, etc. due to their beautiful appearance, good strength and mechanical properties. Fitness equipment, sheet metal processing, decorative advertising, kitchenware and bathroom, household appliances, agricultural and forestry machinery and […]

Application and development of laser welding technology

Laser welding is a non-contact welding process that uses laser energy to join together several different welding materials and then select them into a whole to meet the different requirements of different parts for material properties. Laser welding only applies vertical pressure at the welding point, thereby minimizing the mechanical stress on the product and […]

Unlimited guide of laser welding machine

How Does a Laser Welding Machine Work? A laser welding machine works by focusing a concentrated beam of light, known as a laser, onto the surface of materials to be joined. This intense heat generates a localized melting zone, allowing the materials to fuse together seamlessly. The process typically involves directing the laser beam through […]

The unlimited guide of laser cutting machine

What Are Laser Cutting Machines? Laser cutting machines are tools used in various industries for precision cutting and designing projects. They emit a high-powered laser beam to either cleanly cut or etch a specific design on materials such as steel, plastic, or wood. The beam can either burn, vaporize, or melt away the excess product, […]

New Product JQ Vertical Three Chucks Series

FLT-7028HTS automatic feeding three-chuck CNC laser pipe cutting machine Product Features Overview The bed and chuck adopt a side-mounted connection design to facilitate the loading and unloading of large-diameter pipes.The bed is made of square tubes with a wall thickness of 8~10mm and steel plates ranging from 40mm to 20mm, and is welded together. It […]

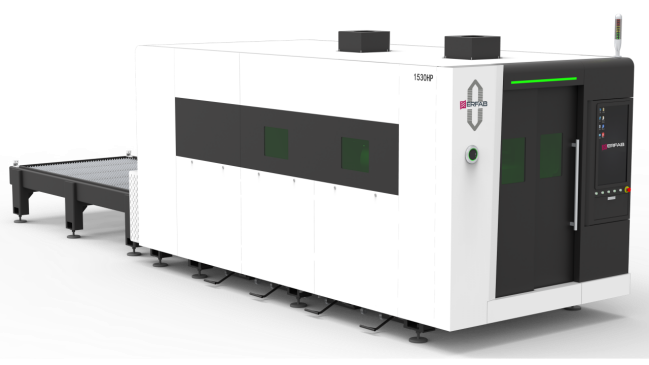

JQ Laser Introduces Upgrades to 1530HP Laser Cutting Machine

Main Features √ Heavy duty machine base. √ High power servo motors. √ Smart cutting control system, easy operation; √ Quick piecing, supported by segment and step piecing technology; √ Specialized air duct with out sized caliber, makes smoke exhaust smooth. √ Fully enclosed design; √ European CE Standard laser protection. √ Dual shuttle tables provides high level of safety and convenience. Mechanical Features: MachineBody The bed structure adopts a plate […]

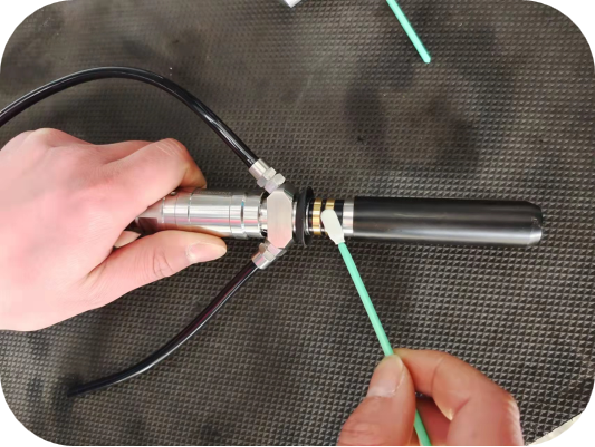

JQ CE welding machine installation instruction

Equipment installation process Host location installation Equipment installation conditions The distance between the side of the equipment and the wall is ≥0.5m, and the distance between the equipment exhaust fan and the wall is ≥1m. The operating environment of the equipment is within 0~45℃ Low humidity and relatively dry (humidity within 20%~80%, no condensation) Less […]

Introduction to Tube and Plate Laser Cutting Machines

The development and widespread adoption of tube and plate laser cutting machines mark a significant technological advancement in the field of manufacturing and fabrication. These machines, embodying the latest in laser technology, have revolutionized the way industries approach material cutting, offering an unmatched blend of precision, efficiency, and versatility. This introduction delves into the intricate […]

What Makes Fiber Lasers Special and Expensive Compared to CO2 Lasers?

Introduction to Fiber Lasers Fiber lasers represent a significant advancement in laser technology, distinguished by their unique design and operational principles. A fiber laser uses an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, or dysprosium as its active gain medium. The design of fiber lasers allows for a high degree of […]

Methods to Extend the Service Life of Laser Tube Cutting Machines: A Comprehensive Guide Focused on FLT-6035ETN

Methods to Extend the Service Life of Laser Tube Cutting Machines: A Comprehensive Guide Focused on FLT-6035ETN Introduction The integration of advanced laser tube cutting machines like the FLT-6035ETN into modern manufacturing processes marks a significant technological advancement. These machines epitomize precision, efficiency, and versatility in metal fabrication. However, their sophisticated nature necessitates a strategic […]