レーザー加工機の品質検査を購入する必要はありますか?

Key Considerations in Laser Cutting Machine Quality Inspection Factor Description Importance Inspection Frequency Determines how often inspections should be performed to maintain optimal machine function. Regular inspections prevent wear and tear, keeping productivity high and minimizing unexpected costs. Precision and Calibration Ensures the machine operates with optimal precision, essential for industries requiring tight tolerances. Calibration […]

プラットフォームや独立したサイトからレーザー切断機のサプライヤーを探す際に注意すべきこと

When you’re in the market for a laser cutting machine, finding a reliable supplier can make or break your purchase. Online platforms and supplier directories offer a wide range of suppliers, but navigating these options effectively requires attention to key details. Here’s a comprehensive guide to help you find the perfect laser cutting machine supplier, […]

購入前に知っておくべきレーザー切断機の保証の秘密

When purchasing a laser cutting machine, the cost of the machine itself is a significant investment, but another equally important factor is the warranty that comes with it. Choosing the right warranty can save you from expensive repair bills and downtime, but navigating the terms and conditions can be tricky. Here’s what you need to […]

チューブ加工におけるレーザーチューブ切断の役割と現状

Laser tube cutting is a transformative technology that utilizes high-powered lasers to precisely cut and shape hollow tubes and metal profiles. This method has revolutionized the manufacturing sector by offering unparalleled accuracy, speed, and flexibility, making it a preferred choice across various industries. Unlike traditional cutting methods that often rely on mechanical blades or saws, […]

ソー・チューブ切断 VS レーザー・チューブ切断

Saw tube cutting VS laser tube cutting is an essential comparison in today’s manufacturing and fabrication industries. This discussion helps professionals decide on the most efficient, cost-effective, and precise cutting methods for tube materials.The choice between saw tube cutting and laser tube cutting can significantly influence manufacturing processes. The traditional saw cutting method is renowned for […]

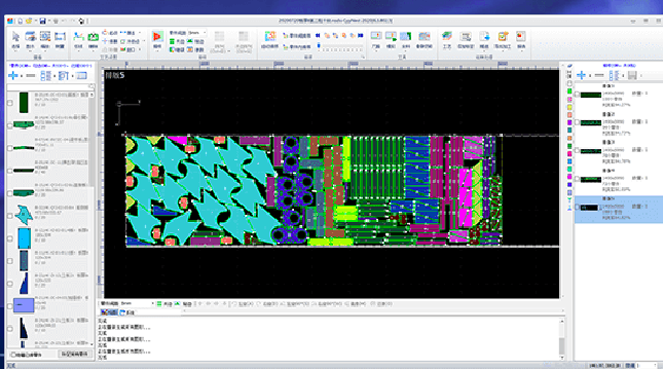

レーザーシート切断のための表面最適化法

Surface optimization method for laser sheet cutting is an advanced technique that enhances cutting efficiency and quality in various industrial applications. With the ever-evolving demands of precision manufacturing, the adaptation of surface optimization methods has become essential in achieving optimal results and maintaining competitive advantage in the market. Surface optimization methods for laser sheet cutting […]

レーザー溶接機現代の産業用途における精度と効率

Laser welding machines have emerged as a game-changing technology in modern industrial applications, offering unparalleled precision and efficiency. These advanced tools utilize high-powered laser beams to join materials, resulting in strong, clean, and highly accurate welds. As industries across the globe strive for higher quality standards and increased productivity, laser welding machines have become an […]

レーザー切断用アレイの作り方

Laser cutting has revolutionized the world of manufacturing and design, offering unparalleled precision and versatility. At the heart of this technology lies a crucial element: the array. Creating an array for laser cutting is an essential skill that can elevate your projects from ordinary to extraordinary. In this comprehensive guide, we’ll delve into the intricacies […]

The importance of laser cutting machine R&D system

Laser cutting machine research and development (R&D) systems play a crucial role in advancing manufacturing technology and capabilities. These systems are responsible for innovating and improving laser cutting machines, which are essential tools in various industries for precise and efficient material cutting.R&D in laser cutting technology focuses on enhancing machine performance, accuracy, speed, and versatility. […]

Laser Applications in Green Technology

Laser Applications Overview Lasers are employed in various sectors to enhance energy efficiency and reduce waste. Key applications include: Table of Related Information Category Description Application Laser technology in green tech Key Benefits Reduces waste, enhances efficiency, promotes sustainability Industries Involved Manufacturing, renewable energy, agriculture, environmental monitoring Technological Advances Development of high-efficiency lasers for various […]