3D Tube laser cutting Machine

Product category introduction

3D Tube Laser Cutting Machine

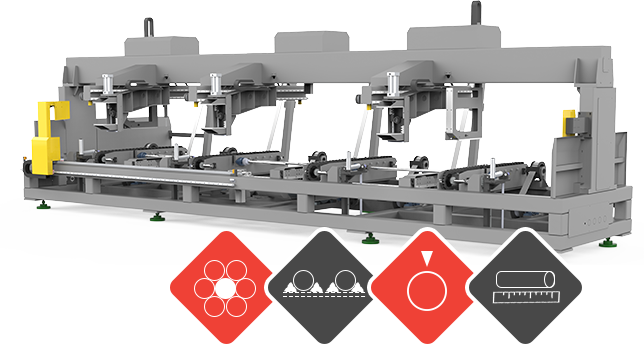

3D tube laser cutting machines are revolutionizing the metal fabrication industry. With the ability to cut complex shapes with precision and accuracy, these specialized machines offer a level of versatility and performance unmatched by any other type of cutting technology available today.

A 3D tube laser cutter is a versatile tool that can be used to cut shaped tubes in virtually mostly shape or size. Whether you need to create intricate designs or simple curves, this type of machine can produce results that are second-to-none. The process involves using high-powered lasers to precisely melt away material from a single piece of tubing, allowing for even more precise cuts than traditional methods could provide. In addition, tubes can be produced faster than ever before due to the increased speed with which these machines operate.

3D Tube laser cutting advantages

Double machine version

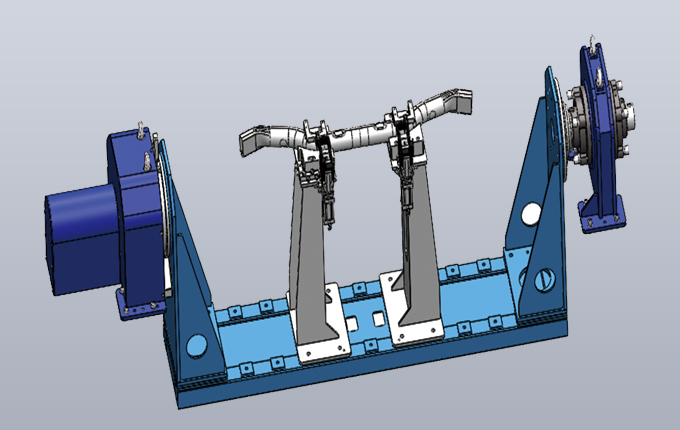

The system is equipped with a double robot, a double laser and a rotating exchange platform, and is suitable for high-volume and efficient cutting of thermoformed workpieces that require fast production schedules. The overall machining efficiency of the workstation can be up to 1.5 times that of a high-speed 5-axis machine.

Customer Needs Analysis

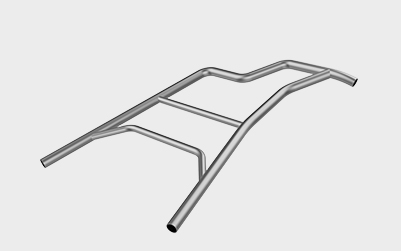

Different shapes of pipe fittings, many kinds of pipe fittings in common line production parts of different lengths, larger sizes need to ring cut both ends and cut holes

One-axis indexing machine

One-axis indexing machine with the rear axle left and right longitudinal beam cutting fixture, for both sides of the ring cut and intermediate cutting, to ensure high precision and high efficiency cutting requirements, to achieve the left and right symmetrical parts mold once, no secondary mold opening, direct intermediate cutting

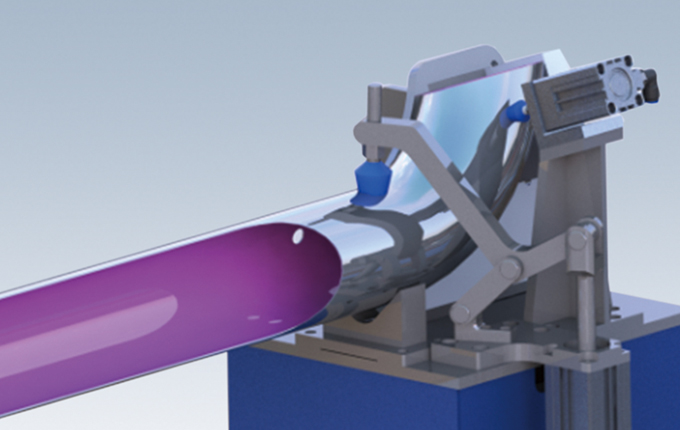

Clamping System

Combined with manual or pneumatic clamping systems, position sensors are equipped to achieve higher repeatable positioning accuracy requirements.

Application Field

3D tube laser cutting machines are becoming the most popular choice for chassis parts in the automotive industry. This technology is quickly replacing traditional methods of cutting, such as machining or plasma torches due to its superior accuracy, speed and better overall quality. 3D tube laser cutting machines use a high-powered laser beam that is able to precisely cut metal tubes with complex shapes and curves, as well as straight lines. The advantages of using this machine include reduced material waste, increased safety during operation and improved quality control over finished parts.

The automotive industry has been quick to adopt this technology because it provides an efficient way of producing chassis components with fewer steps involved in the manufacturing process. This means that automakers can produce more parts faster while still maintaining a high level of quality.

Technology and ability to design machinery

We are living in the age of technology, and this has opened up many opportunities for us to design and create innovative products. One such product is a 3D tube laser cutting machine. This advanced piece of machinery is specifically designed to cut tubes with extreme precision, making it an ideal tool for manufacturing operations.

The use of high-powered lasers allows the machine to deliver clean cuts through different materials with minimal effort. Its 3D capabilities make it easier for users to achieve intricate shapes and designs without having to spend an excessive amount of time on designing or programming the machine itself. With its user-friendly interface, even those who are unfamiliar with operating laser cutters can easily learn how to use it in no time at all.

What we offer is different

As a company that has been in the industry for over 10 years, we have had the opportunity to perfect our craft. In that time, we have become experts in tube laser cutting machines. This allows us to offer our clients a unique advantage—the ability to produce high quality products with a quick turnaround time.

Our team of skilled professionals are able to operate the machines quickly and efficiently, meaning that your project can be completed in a shorter timeframe than if you were to use another company. Additionally, because we have such a high level of experience, we are able to offer competitive pricing without compromising on quality.

If you are looking for a company that can provide you with the best possible service and product, then look no further than us. We guarantee that you will be satisfied with the final product and amazed at how quickly it was completed.

Installation guide and after sale service

JQ Laser provides complete user guidance on installation and use, which has set up a special overseas after-sales department to solve all user problems in a timely manner.The company has been committed to providing users with the best products and services, and has always been highly praised by users. The establishment of the overseas after-sales service department will further enhance the company’s service level and better protect the interests of users.and has successfully helped customers in more than 170 countries and regions to achieve normal operation. JQ Laser will continue to provide users with better products and services, and create more value for users.

JQ Laser has always been proud of its efficient after-sales service and problem solving. We have a team of highly trained and experienced staff who are always ready to help our customers with any issues they may have. We also offer a satisfaction guarantee so that our customers know that they can always expect the best from us.

Order process

In just a few simple steps

During the communication, the salesperson will recommend products and quotes according to your needs.

After placing an order, you will always be provided with product production and logistics information.

After receiving the goods, you will get complete written and online instructions, 24 hours after-sales service.

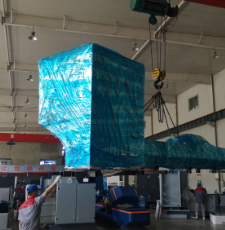

Saving Your Shipping Cost

JQ Laser is the top leader in research and development as well as production capacity in the laser industry. They always consider customer service to be a priority.There are many factors to consider when deciding on the packing size for shipping crates. The most important factor is the safety of the items being shipped. The second factor is the cost of shipping. You want to make sure that you are getting the most bang for your buck when it comes to shipping costs.We take all of these factors into consideration when we design shipping crates for our clients. We analyze the items to be shipped and determine the best packing size that will ensure their safety during transport. We also work with our clients to maximize their logistics cost so they can save money on shipping.Our years of experience and expertise allow us to provide our clients with the best possible packing solution for their needs. Contact us today to see how we can help you with your next shipment.

frequently asked question

Do you have CE? We provide you with CE in the form of a one-stop service. At first, we will demonstrate CE to you. After delivery, we will give you CE packaging list a commercial invoice for customs clearance.

Please tell us about your following answer, our specialist will provide advice on proper power. 1. What material you want to cut, stainless steel, carbon steel or other? 2. What thickness do you want to cut?

If confronted with any problems, please contact us immediately and do not attempt to fix the machine by yourself or anyone else. We will respond within 24 hours as quickly as we can to help you.

2 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Yes, we are happy to provide advice and we have dedicated technicians all around the world who are ready to assist you. Your operations’ continued success relies on your machines staying in working order.

People Also Ask

Can a laser cutter cut 3D?

Laser cutters are incredibly versatile tools that can be used for a range of applications, from cutting and engraving paper to fabricating circuit boards. But what about 3D objects? Can a laser cutter cut 3D? The answer is yes! A laser cutter is capable of cutting and engraving both two-dimensional (2D) materials as well as three-dimensional (3D) objects.

By using specialized software, users can create intricate designs that take advantage of the unique capabilities of a laser cutter. These designs can include detailed contours, edges, curves, and shapes that are not achievable with traditional tools like saws or milling machines. With the right design software and a high-quality laser cutting machine, complex 3D objects can be easily fabricated in only minutes.

What is 3D laser cutting?

3D laser cutting is a type of 3D printing technology that is used to create complex shapes and components from raw materials. It uses a focused beam of light, usually from an industrial-grade laser, to cut or engrave the material into the desired shape or design. This process can be used for many different types of applications such as creating jewelry, automotive parts, and industrial tools.

The 3D laser cutting process involves using CAD (Computer Aided Design) software to create the desired shape. Once the file is uploaded into the machine, it will use its computer-controlled optics system to direct the laser accurately along specified paths in order to cut or engrave the material according to exact specifications. Depending on what type of material is being cut or engraved, there are several different settings that need to be adjusted in order for optimal results.

Оставьте сообщение и получите ответ

Для того чтобы улучшить опыт пользователей и усовершенствовать наши производственные технологии, JQ laser собирает реальные вопросы и комментарии по обработке машин с рынка, которые мы будем анализировать и предоставлять ответы, а также мы будем принимать благоприятные производственные идеи.