How Laser and TIG Welding Harmonize in Today’s Job Shops

In the modern job shop, laser and TIG welding coexist as complementary techniques, each offering unique advantages that cater to different needs within the fabrication process. The integration of these two methods allows job shops to maximize efficiency, precision, and versatility, addressing a wide range of welding requirements.Laser welding is renowned for its precision and speed. It uses a focused laser beam to join materials, creating a small heat-affected zone and allowing for high-quality welds with minimal distortion. This method is particularly advantageous for applications requiring tight tolerances and high-speed production, such as in the aerospace, electronics, and automotive industries. On the other hand, TIG welding, which stands for Tungsten Inert […]

Laser Welding vs. TIG Welding

Laser welding and TIG (Tungsten Inert Gas) welding are two prominent techniques used in the metalworking industry, each with its own set of advantages and applications. Understanding the differences between these methods can help manufacturers choose the right technique for their specific needs.Laser welding is a high-precision technique that uses a laser beam to join metals. It is known for its speed, accuracy, and ability to weld hard-to-reach areas with minimal distortion. This method is ideal for applications requiring high-quality welds and is commonly used in the automotive, aerospace, and electronics industries. Laser welding provides a concentrated heat source, allowing for narrow, deep welds and high welding rates.On the other […]

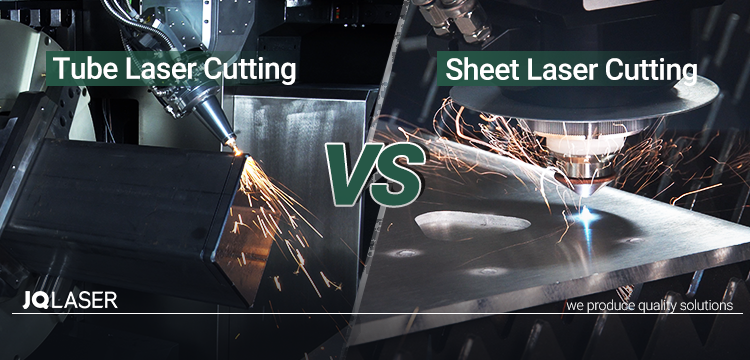

Why Tube Laser and Sheet Metal Cutting Speeds Differ

The speed difference between tube laser cutting and sheet metal cutting is a topic of significant interest in the manufacturing industry. While both technologies utilize laser cutting, their applications and efficiencies differ due to the inherent complexities of the materials and shapes they handle. Complexity of Tubular Workpieces One of the primary reasons tube lasers operate at slower speeds compared to sheet metal cutters is the complexity of the workpieces involved. Tubes often have varying thicknesses, weld seams, and differing corner radii, which require more precise handling and slower cutting speeds to maintain quality. In contrast, sheet metal is typically flat and uniform, allowing for faster processing speeds.In tube laser […]

Laser cutting VS Water jet cutting

What is laser cutting? Laser cutting is a technology that uses a laser to cut materials. It is commonly used in industrial manufacturing applications but is also starting to be used by hobbyists. Laser cutting can be used to cut through a variety of materials, including wood, metal, and plastic. Laser cutting works by using a focused beam of light to heat up the material that it is cutting. The heat from the laser melts or vaporizes the material, making it easy to cut through. Laser cutting is a very precise process, which makes it ideal for cutting complex shapes or patterns. One of the big advantages of laser cutting […]

Fiber Laser VS CO2 Laser

Introduction In the world of laser technology, two types of lasers have gained significant prominence: fiber lasers and CO2 lasers. These lasers are widely used in various industries and have revolutionized the way materials are processed. In this article, we will delve into the differences between fiber lasers and CO2 lasers, exploring their working principles, advantages, and applications. So, let’s get started and understand how these lasers differ from each other. Understanding Fiber Lasers 2.1 What is a Fiber Laser? A fiber laser is a type of laser where the active gain medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, or neodymium. The laser beam […]