Laser cutting principle

Laser cutting uses a focused high-power, high-energy-density laser beam to irradiate onto the plate to be processed, causing the irradiated material to quickly melt, vaporize, ablate or reach the ignition point. The high-speed airflow blows away the molten material and cuts the sheet.

Precautions during the production process of laser cutting equipment

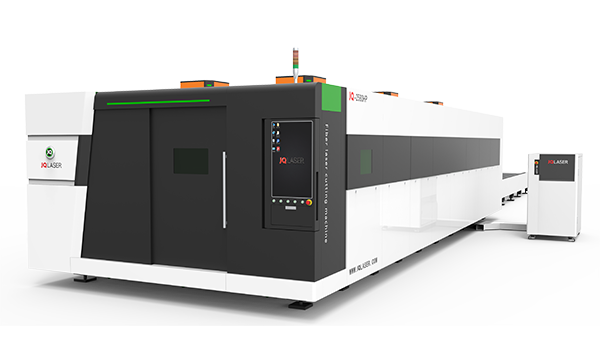

Equipment procurement

There are many domestic laser equipment manufacturers, but there are not many leading companies that master key technologies. The purchase of large equipment must go through various forms of research, investigation and consultation. Laser power is the main factor that determines work efficiency and the ability to cut plate thickness. Therefore, laser power should be selected according to actual production needs. High power cannot be chosen blindly, because the greater the power, the greater the equipment consumables and usage costs. The choice of work surface must be determined based on the actual conditions of production and use. In order to improve work efficiency, the author recommends purchasing an exchange workbench. Consumables are the main component of equipment usage costs. Whether the consumables are versatile and easy to purchase is also a key factor in equipment procurement. After-sales service is a practical issue that must be considered when choosing equipment manufacturers, especially high-power laser equipment. The equipment is of high value, and its maintenance and use require very professional technical guidance. High-quality after-sales service will reduce a lot of worries in future equipment use.

Equipment use and maintenance Lens maintenance

The surface of the optical lens should be kept clean and avoid direct contact with hands or objects, as this may easily cause scratches on the mirror surface. During the production process, the mirror surface will often be stained with dust, which will lead to a decrease in cutting quality, and even cause the temperature of the cutting head to be extremely high, causing the equipment to alarm and shut down. Workers should promptly use soft tissue paper and alcohol to wipe the lens to ensure it is smooth and clean. If the alarm cannot be effectively improved or relieved, the protective lens should be replaced in time. Maintenance of the cutting head: The coaxiality of the center of the cutting head and the laser is a key inspection point when using the equipment. The center deviation of the cutting head will lead to defects such as incomplete cutting, poor slag discharge, and rough cutting surface. After replacing the cutting head, technicians must carefully adjust the concentricity between the nozzle center and the laser. They can use adhesive paper to stick in contact with the cutting head, and then tear it off to check the contact traces between the adhesive paper and the cutting head to check the concentricity of the cutting head. degree, and adjust repeatedly until completely concentric. In addition, the cutting head is easily stained with melt stains during use. In severe cases, the cutting quality will be poor, or even cutting will not be possible, and the equipment will alarm. It should be cleaned or replaced in time.

Selection of cutting feed speed

Observe the shape of the cutting sparks to judge whether the feed speed is appropriate: (1) The cutting sparks spread from top to bottom, and spread evenly front and back, the cutting surface presents a smooth line, and the lower half has no Melting stains are produced at a moderate speed. (2) The cutting sparks tilt backward and the cutting speed is too fast. The cutting speed should be slowed down. (3) The cutting sparks do not spread and the sparks are small and condensed together. This is caused by excessive power or too slow speed. The speed should be increased.

Production quality management and subsequent process processing

Cutting production should follow the production quality control procedures of first inspection – patrol inspection – final inspection. Conducting the first inspection of cutting samples can promptly detect errors in product programming dimensions and correct them in a timely manner, which can prevent large-scale dimensional errors. The inspection process focuses on checking the cutting quality of the product to prevent abnormalities in key indicators such as the cutting nozzle, lens, and air pressure during the cutting process. Even if abnormalities occur, they can be dealt with in a timely manner to ensure the consistency of product quality. The laser cutting machine adopts a precision control method of dual-track and three-axis linkage. The positioning accuracy can reach 0.05mm, and the repeated positioning accuracy can reach 0.02mm, which completely eliminates the deviation that occurred in the previous drilling positioning. After repeated cutting measurements and experiments, high-power laser (20000W) cutting equipment has a bevel angle of 0.25~0.31° when the plate thickness is 36mm~40mm; and when the plate thickness is 8mm~32mm, the bevel angle is 0°~0.15°. Therefore, after the processing is completed, the construction personnel should also perform 1×45° chamfering on the edge of the hole. After experimental comparison, the taper and hole edge have little effect on the shear of the stressed bolt. After the product is cut, the construction personnel should polish and sand blast around the product to remove the cutting edge. Sand blasting can effectively reduce cutting burrs, rust, etc., which is conducive to orderly hot-dip galvanizing processing and can improve the quality of the product. Zinc layer adhesion after galvanizing.

Conclusion

With the maturity of laser cutting technology, high-power laser equipment has been promoted, and the market price has also dropped significantly. The emergence of 20,000 to 30,000 watt laser cutting equipment has given us more advanced intelligent processing technology. The use of high-power cutting technology can effectively improve production efficiency, reduce product production energy consumption, improve product quality, and reduce production costs. It is in line with an energy-saving, green, efficient, and intelligent modern production model, and can effectively improve the production of joint-plate power hardware products. efficiency, product quality, and shorten the company’s delivery cycle.