Tube laser cutting machines are an essential tool in the manufacturing industry, providing high precision and efficient cutting capabilities for a variety of materials. In this article, we will explore the different cutting capabilities of a tube laser cutting machine and how it can be used in various applications. We will discuss the different types of lasers used in these machines, the materials they can cut, and the advantages of using a tube laser cutting machine over other cutting methods. By understanding the capabilities and limitations of a tube laser cutting machine, manufacturers can make informed decisions about the best equipment for their specific needs.

Tube Laser Cutting

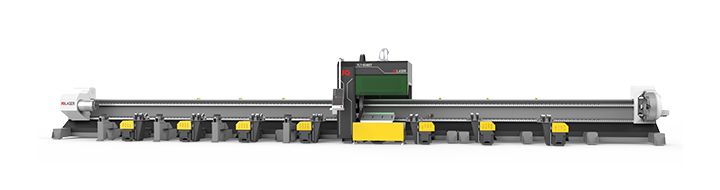

Tube laser cutting is a manufacturing process that involves using a laser to cut precise shapes and profiles out of tubes made of metal or other materials. The laser beam is generated by a laser source and is focused and directed through a set of optics to the cutting head, which houses the focusing lens and nozzle. The cutting head is mounted on a movable carriage, which can be controlled by a computer numerical control (CNC) system to position the laser beam at specific points on the workpiece.

Types of Tubes Used

Tube laser cutting machines can be used to cut a variety of tubes made of different materials. Some common types of tubes that are used in laser cutting include:

- Metal tubes: Metal tubes are the most common type of tubes used in laser cutting, and include materials such as steel, aluminum, brass, and copper. Metal tubes are often used in the automotive, aerospace, and construction industries.

- Plastic tubes: Plastic tubes can be cut using laser cutting machines, and are often used in the medical, automotive, and furniture industries.

- Glass tubes: Glass tubes can be cut using laser cutting machines, and are used in a variety of applications, including scientific instruments, lighting, and decorative elements.

- Composite tubes: Composite tubes, which are made of a combination of materials such as carbon fiber and resin, can also be cut using laser cutting machines. These tubes are used in the aerospace and sporting goods industries.

Benefits of Tube Laser Cutting

Tube laser cutting has a number of benefits over traditional manufacturing processes, including:

- High precision: Laser cutting machines are able to produce cuts with high precision and accuracy, with tolerances as low as 0.1mm.

- Efficiency: Tube laser cutting is a highly efficient process that can produce parts in a short time, with minimal material waste.

- Complex shapes: Laser cutting machines are able to cut complex shapes and profiles that would be difficult or impossible to produce using other methods.

- Minimal material distortion: Laser cutting generates minimal heat, which helps to prevent warping or distortion of the material.

- Versatility: Laser cutting machines can be used to cut a wide range of materials, including metals, plastics, and wood.

- Cost-effectiveness: Laser cutting can be more cost-effective than other manufacturing processes, especially for small batch production or prototyping.

Advantages of Automated Process

Tube laser cutting machines are automated systems that use a laser beam to cut tubes made of metal or other materials into specific shapes and profiles. The use of automation in the cutting process offers a number of advantages over traditional manual methods, including:

- Increased precision: Automated laser cutting machines are able to produce cuts with a high degree of accuracy and repeatability, with tolerances as low as 0.1mm.

- Greater efficiency: Automated laser cutting machines can operate at a faster pace and with minimal material waste, resulting in higher productivity and lower costs.

- Improved consistency: Automated laser cutting machines can produce parts with consistent quality, reducing the risk of defects or variations in the finished product.

- Enhanced safety: Automated laser cutting machines minimize the need for manual handling of materials, which can help to reduce the risk of injury to workers.

- Greater flexibility: Automated laser cutting machines can be programmed to cut a wide range of shapes and profiles, and can be easily adapted to new designs or requirements.

Efficient Cutting of Various Shapes

Tube laser cutting machines are capable of cutting complex shapes and designs with ease. Whether it’s round, square, rectangular, or even elliptical tubes, these machines can handle them all. The precise control over the laser beam allows for intricate cuts, enabling manufacturers to create customized components and parts.

High Precision and Accuracy

Precision is paramount in manufacturing, and tube laser cutting machines excel in this aspect. With their advanced laser technology and computer-controlled systems, they can achieve exceptional accuracy, ensuring that each cut is precise and consistent. This level of precision eliminates the need for additional machining processes, saving time and costs.

Speed and Productivity

Tube laser cutting machines are known for their remarkable speed and productivity. The laser beam can rapidly cut through the material, significantly reducing production time compared to traditional cutting methods. This increased efficiency allows manufacturers to meet tight deadlines and handle large production volumes.

Clean and Burr-Free Cuts

When it comes to quality cuts, tube laser cutting machines deliver outstanding results. The laser beam produces a narrow heat-affected zone, minimizing material distortion and preventing the formation of burrs. This clean cutting process eliminates the need for additional finishing operations, enhancing overall efficiency.

Cost-Effectiveness and Material Optimization

Tube laser cutting machines offer cost-effective solutions for manufacturers. The precise cutting capabilities reduce material waste, optimizing material usage and minimizing costs. Additionally, the elimination of secondary processes and the speed of the cutting process contribute to overall cost savings.

9. Limitations of Tube Laser Cutting

While tube laser cutting machines offer numerous benefits, they also have some limitations. For instance, the size of the tube that can be processed is limited by the machine’s specifications. Additionally, certain materials, such as reflective metals, may pose challenges for laser cutting due to their high reflectivity.

Conclusion

Tube laser cutting is a highly precise and efficient manufacturing process that is used in a wide range of industries to produce components and parts with high accuracy and repeatability. Tube laser cutting machines are automated systems that use a laser beam to cut tubes made of metal or other materials into specific shapes and profiles. The use of automation in the cutting process offers a number of benefits, including increased precision, efficiency, consistency, and safety. Tube laser cutting machines can cut a wide range of materials, including metals, plastics, wood, glass, and composites. The cost of using a tube laser cutting machine will depend on a variety of factors, including the initial investment, operating costs, material costs, and labor costs. Overall, tube laser cutting is an important manufacturing process that has a wide range of applications in various industries.