Introduction

Tube laser cutting machine is a modern cutting technology used for cutting various metal hollow round tube materials such as aluminum, copper, brass, and steel. It is a precise, high-speed, and cost-effective cutting method that is used in a variety of industries. The laser beam is focused on the tube to be cut and the material is cut with high precision and accuracy. The laser beam is directed and focused on the material to be cut, which is then melted and vaporized due to the extreme heat. The end result is a precise, clean, and smooth cut. The laser tube cutting process also eliminates the need for secondary machining, which reduces the cost of production and increases efficiency. With the help of laser tube cutting, complex shapes and intricate details can be cut with ease.

Understanding the Different Types of Tube Laser Cutting Machines

Tube laser cutting machines are an essential tool for a variety of industrial applications. These machines are used to cut and shape metal tubes, pipes and other materials with a high degree of precision and accuracy. There are several types of tube laser cutting machines, each with its own advantages and disadvantages.

The first type of tube laser cutting machine is a rotary laser. This type of machine is used to cut round tubes, pipes and other circular shapes. The rotary laser is equipped with a rotating head and a beam of laser light that is focused on the material being cut. This type of machine is most suitable for cutting large diameter tubes and pipes, and is commonly used in manufacturing and automotive industries.

The second type of tube laser cutting machine is a flatbed laser. This type of machine is used to cut flat materials such as sheet metal, aluminum, steel and other sheet materials. The flatbed laser is equipped with a long beam of laser light that is directed onto the material being cut. This type of machine is capable of producing highly accurate and precise cuts, making it a favorite among manufacturers and fabricators.

The third type of tube laser cutting machine is a tube laser cutting machine with an integrated optical system. This type of machine is equipped with an optical system and a laser head that is able to cut both round and flat materials with equal precision and accuracy. This type of machine is often used in the automotive industry to cut pipes and other metal parts.

Finally, there is the hybrid laser cutting machine. This type of machine is designed to cut both round and flat materials, and is equipped with both a rotary and flatbed laser head. This type of machine is usually used in the aerospace and automotive industries, and is capable of cutting complex shapes with precise accuracy.

No matter what type of tube laser cutting machine you choose, it is important to understand the advantages and disadvantages of each type. In addition, it is important to consider the size and complexity of the job when selecting the right machine for your needs. With the right machine and proper training, you can ensure that your projects are completed with the highest level of accuracy and precision.

Exploring the Benefits of Tube Laser Cutting Machines

Tube laser cutting machines offer increased efficiency and accuracy. The laser beam is directed through a computer-controlled program, allowing for fast and accurate repeatability. This method is much faster than traditional cutting methods, allowing for higher production rates and shorter lead times. The laser also ensures accuracy and repeatability, reducing scrap and allowing for tight tolerances.

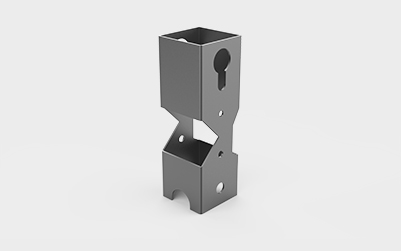

Tube laser cutting machines are also highly versatile. They are able to quickly and accurately cut tubes and profiles of almost any size and shape. The laser can cut round, square, and rectangular tubes, as well as channels, angles, and other shapes. This increased versatility makes tube laser cutting machines ideal for a variety of applications, from small-scale prototyping to large-scale production runs.

Tube laser cutting machines also offer improved safety. The laser beam is contained within the machine, eliminating the need for operators to be near the cutting area. Additionally, the laser requires no special ventilation or gases, reducing the potential for hazardous emissions.

Finally, tube laser cutting machines offer a higher quality of cut. The laser beam is focused and concentrated, allowing for a smooth and precise finish. This eliminates the need for additional finishing operations and reduces the amount of time and resources required for the final product.

Overall, tube laser cutting machines offer numerous advantages over traditional methods of cutting. They provide faster, more accurate results with fewer secondary operations, increased versatility, improved safety, and a higher quality of cut. As such, these machines are becoming increasingly popular in the fabrication industry and are sure to remain a staple in the years to come.

What Industries Benefit Most from Tube Laser Cutting Machines?

Tube laser cutting machines are a revolutionary technology that offer a wide range of advantages for businesses in many industries. This technology has revolutionized cutting processes in many industries, offering faster and more accurate cuts, as well as greater flexibility and cost savings. Industries that benefit the most from tube laser cutting machines include automotive, aerospace, construction, medical, and manufacturing.

In the automotive industry, tube laser cutting machines are used to cut components for cars, trucks, and other vehicles. This technology enables faster and more accurate production of parts, with greater flexibility and cost savings than traditional cutting methods. It also allows for more efficient production of complex parts with intricate designs.

In the aerospace industry, tube laser cutting machines are used to cut components for aircraft and spacecraft. This technology enables faster and more accurate production of parts, with greater flexibility and cost savings than traditional cutting methods. It also allows for more efficient production of complex parts with intricate designs.

In the construction industry, tube laser cutting machines are used to cut components for buildings and other large structures. This technology enables faster and more accurate production of parts, with greater flexibility and cost savings than traditional cutting methods. It also allows for more efficient production of complex parts with intricate designs.

In the medical industry, tube laser cutting machines are used to cut components for medical devices and instruments. This technology enables faster and more accurate production of parts, with greater flexibility and cost savings than traditional cutting methods. It also allows for more efficient production of complex parts with intricate designs.

In the manufacturing industry, tube laser cutting machines are used to cut components for a variety of products. This technology enables faster and more accurate production of parts, with greater flexibility and cost savings than traditional cutting methods. It also allows for more efficient production of complex parts with intricate designs.

Overall, tube laser cutting machines offer a wide range of benefits for businesses in many industries. This technology has revolutionized cutting processes in many industries, offering faster and more accurate cuts, as well as greater flexibility and cost savings. Industries that benefit the most from tube laser cutting machines include automotive, aerospace, construction, medical, and manufacturing.

Tips for Improving the Quality of Your Tube Laser Cutting Projects

- Choose a Quality Tube Laser Machine: Investing in a high-quality tube laser cutting machine is essential for achieving successful projects. Look for machines with features such as high accuracy, repeatability, and a large cutting envelope, as these will enable you to achieve the best results.

- Inspect the Material: It’s important to inspect the material for any imperfections before beginning a tube laser cutting project. Look for any dents, scratches, or other irregularities that could affect the quality of the cut.

- Prepare the Material: Ensure that the material is securely clamped and that the surface is free from debris or other contaminants. If the material is not properly secured, the laser may produce inaccurate results.

- Use Quality Settings: Adjust the settings on the tube laser machine to the recommended settings for the material and size of the tube you are cutting. This will ensure that the cuts have the best quality and accuracy.

- Follow the Recommended Process: Follow the manufacturer’s instructions and recommendations for the most successful results. This will help you avoid any unexpected issues or problems.

- Use Quality Gases: The gases used in the tube laser cutting process can affect the quality of the finished product. Invest in quality gases to ensure that your projects are successful.

- Inspect the Final Product: Once the tube laser cutting process is complete, it’s important to inspect the final product for any imperfections. This will enable you to identify any potential issues before the product is delivered to the customer.How to Maintain Your Tube Laser Cutting MachineTube laser cutting machines are an excellent choice for businesses that need to cut high-quality parts from metal tubing. The machines are capable of producing complex cuts, such as inner and outer bevels, as well as straight, curved, and spiral cuts. However, in order to ensure these machines continue to produce accurate parts, it is essential to maintain them. Here are some tips for how to maintain your tube laser cutting machine:

- Regularly clean the optics. The optics of a tube laser cutting machine are what allow the laser beam to accurately cut the material. Over time, dirt, dust, and other particles can build up on the optics and reduce the accuracy of the cuts. Therefore, it is important to regularly clean the optics with a lint-free cloth.

- Check and adjust the laser beam alignment. The laser beam needs to be aligned correctly in order to produce accurate cuts. This alignment should be checked regularly and adjusted as needed.

- Monitor the gas pressure. The gas pressure of the laser cutting machine needs to be monitored regularly to ensure that it is within the recommended range. If the pressure is too low or too high, it can affect the accuracy of the cuts.

- Check for loose screws and bolts. It is important to periodically check the frame of the machine for loose screws and bolts. Loose screws and bolts can cause the frame to vibrate and thus affect the accuracy of the cuts.

- Lubricate the moving parts. The moving parts of the machine should be lubricated regularly in order to prevent them from becoming rusty or seizing up.

Following these tips can help you keep your tube laser cutting machine in peak condition and ensure that it produces high-quality parts.

Conclusion

In conclusion, tube laser cutting machines are mainly used for cutting various metal hollow round tube materials. They provide high precision and accuracy, as well as speed and cost efficiency. This makes them ideal for a variety of industries and applications, such as automotive, aerospace, and medical device manufacturing. They are also highly reliable and require minimal maintenance. Thus, tube laser cutting machines are an excellent choice for cutting metal hollow round tube materials with precision and accuracy.