Introduction

Tube laser cutting parts are used in many industries and are essential for many projects. With the advancements in laser cutting technology, it is now easier than ever to produce high-quality parts. This article will provide tips on how to improve tube laser cutting parts. By following these tips, you can get better results from your laser cutting machine and produce parts of higher quality. We will discuss topics like proper machine setup, material selection, and the best cutting parameters. We will also provide some examples of how laser cutting can be used to improve parts. With the right knowledge, you can maximize the efficiency and accuracy of your tube laser cutting operations.

Understanding the Basics of Tube Laser Cutting and How to Improve Parts Quality

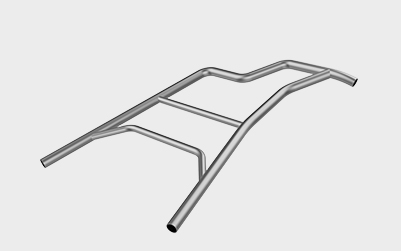

Tube laser cutting is a highly accurate process with a very high level of repeatability. This makes it ideal for producing parts with tight tolerances and complex geometries. The process is also very efficient, with minimal waste, and it can be used to cut a wide variety of materials, including stainless steel, aluminum, brass and copper.

To ensure the highest quality parts, it is important to understand the basics of tube laser cutting. The first step is to select the right machine for the job. Different machines offer different capabilities and features, so it is important to choose one that meets the needs of the application. The laser beam must also be properly aligned and focused to ensure the highest quality cut.

Once the machine is set up and ready to go, the material to be cut should be properly prepared. This includes making sure the material is free of any burrs, scratches or other imperfections. It is also important to ensure that the material is properly clamped and secured in place to avoid any movement during the cutting process.

In order to achieve the best possible results, it is also important to use the right cutting parameters. This includes selecting the appropriate laser power and speed for the material type and thickness. The cutting speed should also be adjusted to suit the size and shape of the part being cut.

Finally, it is important to inspect and measure the parts after the cutting process has been completed. This will help to ensure that all parts meet the required specifications and that there are no imperfections.

Determining the Best Machine Settings for Optimal Tube Laser Cutting Performance

The most important machine setting for tube laser cutting is the power level. Higher power settings are well-suited for thicker materials, while lower settings are better for thinner materials. The speed of the cutting process is also influenced by the power setting, with higher power settings providing faster cutting speeds. Additionally, the power setting must be adjusted according to the material being cut to ensure the laser beam has enough energy to penetrate the material without damaging it.

The speed setting is also an important factor in tube laser cutting. This setting determines the rate at which the laser beam is moved across the material. A higher speed setting will produce a faster cut, but can lead to less precise cuts. Conversely, a lower speed setting may produce a slower cut but will result in more accurate cuts. It is important to find the balance between speed and accuracy that is best suited for the job.

The focal length of the machine is another important setting. This setting determines the size of the laser beam and the depth of the cut. A shorter focal length produces a smaller beam and shallower cuts, while a longer focal length produces a larger beam and deeper cuts. The focal length should be adjusted according to the thickness of the material being cut and the desired depth of the cut.

Finally, the nozzle size should be adjusted according to the material being cut and the desired cut quality. Smaller nozzles are better suited for fine, detailed cuts, while larger nozzles can provide faster cutting speeds but at the cost of accuracy.

What Factors Affect Tube Laser Cutting Accuracy and How to Improve It

One of the primary factors that affect tube laser cutting accuracy is the size of the tube. If the size of the tube is too small, it can cause the laser to overheat, resulting in inaccurate cuts. Likewise, if the tube is too large, it can cause the laser to underperform, resulting in inaccurate cuts. It is important to ensure that the size of the tube is within the recommended size range for the type of machine being used.

The quality of the material used to create the tube can also affect the accuracy of the cuts. If the material is of poor quality, it can cause the laser to deviate from the expected cutting path. It is important to make sure that the material used is of good quality, so that the laser has a clean and consistent cutting path.

The power of the laser is also a factor that affects tube laser cutting accuracy. If the power of the laser is too low, it can cause the laser to cut too slowly and produce inaccurate cuts. Likewise, if the power of the laser is too high, it can cause the tube to overheat and produce inaccurate cuts. It is important to make sure that the power of the laser is set to an appropriate level for the type of material being cut.

Finally, the alignment of the tube is also a factor that affects tube laser cutting accuracy. If the tube is not properly aligned, the laser may not be able to cut along the desired cutting path. It is important to make sure that the tube is properly aligned before beginning the cutting process.

Identifying Common Tube Laser Cutting Defects and How to Avoid Them

The most common defects in tube laser cutting are caused by contamination, poor beam quality, and incorrect material selection. Contamination occurs when particles of dust, dirt, grease, or other materials get into the system. This can affect the accuracy of the cut and may result in warping, poor surface finish, or cracks. Poor beam quality can occur when the laser beam is unfocused or misaligned, causing uneven or inaccurate cuts. Lastly, incorrect material selection can lead to poor cutting performance.

Fortunately, these defects can be avoided with proper care and attention. To reduce the risk of contamination, the system should be kept clean and free of debris. Furthermore, regular maintenance should be performed to ensure that all components are in good working condition. Additionally, the laser beam should be checked regularly to make sure it is properly focused and aligned.

Finally, material selection is paramount in ensuring a successful tube laser cutting project. It is important to select a material that is compatible with the laser cutting process, as well as suited to the desired application. Doing so will help to ensure good cutting performance and reduce the risk of defects.

Optimizing Tube Laser Cutting Processes

Achieving the best results from tube laser cutting involves various strategies that encompass both design and execution.

Design Considerations

Before the cutting process even begins, thoughtful design is crucial. Creating parts with efficient nesting, minimal wasted space, and appropriate support structures can significantly enhance the outcome.

Precision Programming and Simulation

Utilizing advanced software, programmers can simulate the cutting process virtually. This step helps identify potential issues and refine the programming before actual cutting begins, saving both time and material.

Real-time Monitoring and Adjustment

Modern tube laser cutting machines often feature real-time monitoring capabilities. Operators can observe the process in detail and make adjustments on-the-fly to ensure the desired results.

In the next section, we’ll discuss the maintenance and care required to keep laser cutting machines in optimal condition.

Maintenance and Care for Laser Cutting Machines

Maintaining tube laser cutting machines is essential to ensure consistent performance and extend their lifespan.

Regular Cleaning and Inspection

Dust, debris, and residue from the cutting process can accumulate and affect the machine’s precision. Regular cleaning and inspection routines help prevent these issues.

Lens and Nozzle Replacement

The lens and nozzle components of the laser system can degrade over time. Periodic replacement ensures that the laser’s focus remains sharp and consistent.

As we move forward, we’ll explore techniques to enhance the efficiency of tube laser cutting processes.

Exploring the Benefits of Using Different Laser Cutting Gases to Improve Tube Laser Cutting Parts

When it comes to manufacturing components and parts, the use of laser cutting technology is becoming increasingly popular. Laser cutting offers a number of advantages over more traditional cutting methods, including higher precision and faster speed. However, one of the most important factors in achieving optimal laser cutting results is the choice of gas used during the cutting process. Different laser cutting gases can have a significant effect on the quality of the cut, as well as the overall performance of the laser cutting machine.

When it comes to laser cutting, there are a variety of different gases that can be used, each with its own set of benefits. For tube laser cutting, the most commonly used gases are nitrogen, oxygen, and argon. Nitrogen is a cost-effective choice for laser cutting, and it is often used for cutting a variety of materials, including stainless steel and aluminum. It is a good choice for small parts and can provide good accuracy. However, it is not suitable for large parts as it can cause warping.

Oxygen is another common laser cutting gas, and it is often used for cutting thicker materials such as steel. It is a good choice for parts that require a deep cut, as oxygen is highly reactive and will create a clean, smooth cut. It also helps to reduce burning and discoloration of the edges.

Finally, argon is a highly effective laser cutting gas that is used for a wide range of applications, including tube laser cutting. It is a good choice for cutting a variety of materials including aluminum, steel, and titanium. It is odourless and non-toxic, which makes it safe to use in enclosed areas. Argon is also very efficient at removing heat from the cutting area, allowing for a more precise and accurate cut.

Best Practices for Maintaining Tube Laser Cutting Equipment to Ensure Optimal Cutting Performance

Tube laser cutting is a cost-effective, precision-cutting method that is used in a wide range of industries. However, for optimal cutting performance, it is important to maintain your tube laser cutting equipment properly. This article outlines best practices for maintaining your tube laser cutting machinery to ensure optimal performance.

- Regularly Clean the Machinery. It is important to keep your tube laser cutting machinery clean in order to maintain optimal performance. This means wiping down the machinery regularly to remove dust and debris. Additionally, it is important to ensure that there is no buildup of residue on any of the surfaces, as this can affect the cutting performance of the machine.

- Check the Alignment. It is also important to regularly check the alignment of the machine, as misalignment can lead to poor cutting performance. You should check the alignment of the laser beam, the cutting head, and the focus lens to ensure that all components are properly aligned.

- Replace Worn Parts. Over time, components of the tube laser cutting machinery can become worn and need to be replaced. This includes the cutting head, the focus lens, and other components that may become worn with use. It is important to replace these components as soon as they become worn, as this will ensure optimal cutting performance.

- Check the Cooling System. The cooling system is essential for optimal performance of the tube laser cutting equipment. It is important to check the cooling system regularly to ensure that it is functioning properly, and that there are no leaks or blockages.

- Perform Regular Maintenance. Regular maintenance is essential for optimal performance, and should include a thorough inspection of the machinery. This should include checking for wear and tear on any components, as well as checking for any potential problems that may be impacting the performance of the machine.

Conclusion

Tube laser cutting has become an essential tool in modern manufacturing processes. With the right techniques and tools, it can provide accurate and precise parts. To ensure the best results, manufacturers must be aware of the different types of tube laser cutting processes, the best materials to use, and the correct machine settings. In addition, they must take steps to maximize the efficiency of the process and minimize waste. By understanding the fundamentals of tube laser cutting, manufacturers can optimize the process and produce high-quality parts with the least amount of effort.